Solid timber is natural, beautiful and cozy

Building projects evolve with binderholz solid timber products and construction solutions, which all standard requirements in terms of structural physics and fire protection. Solid wood buildings retain their value, are stable and meet the most stringent demands on quality, cost-effectiveness and ecological sustainability.

In order to guarantee this, all binderholz construction solutions are developed with practicality in mind. They are comprehensively tested and certified. Moreover, they make fast, dry, clean and quiet building possible. Owing to the extensive research, development and certification work on the part of binderholz, solid timber buildings can be technically realized today - within the framework of what's possible under the building law - so they reliably meet all applicable building standards.

A broad range of successfully implemented reference properties and a constantly rising demand provide proof that solid timber construction is very popular as well as being commercially competitive.

Yet, alongside these technical and commercial factors, there are other good arguments in favor of solid timber construction.

Coziness and air quality

Solid timber stands for well-being and living comfort. The broad scope of design options that opens up to the architect is certainly one factor to ensure this. Inside the building, for example, the visible surfaces of different wood species such as spruce, Swiss pine, silver fir or BBS Antique can be combined and further customized by color glazes as well as by polished or brushed surfaces. In conjunction with the outstanding properties of the wood substance as a storage for heat and moisture, the warm wooden surfaces ensure a well-balanced living climate and a high level of living comfort.

Slim, lightweight designs with a high degree of prefabrication

binderholz construction solutions allow for a high degree of prefabrication. It shortens building times considerably while always maintaining high quality. In addition, solid timber constructions have an attractive ratio in terms of gross and net living space compared to conventional methods. Especially in the urban space, this has become increasingly important when considering the building costs. Intelligent combinations of solid timber and conventional building materials such as concrete, steel and glass can result in cost-efficient hybrid solutions, which combine the advantages of traditional materials with the merits of solid timber construction. The comparatively low weight of solid wood is a great advantage, for example. When building another story to a building, this strength is literally brought to bear. Solid timber wins the argument here on account of its structural possibilities and the fact that the load on the building, owing to the low weight, is not substantially increased.

Eco-bonus wood

When it comes to aspects of environmental protection, wood as a natural raw material has numerous advantages over conventional building materials.

Wood ...

... has a soothing effect and increases well-being

... is constantly regrowing in sufficient amounts

... is a natural carbon sink; it binds CO2 and is thus actively contributing to climate protection

... is a natural energy storage

... can be 100% ecologically recycled

Criteria such as ecology, sustainability, life cycle costs, recycling and a conservative use of resources play an ever more important role when it comes to the question of suitable construction solutions and building materials. Solid timber construction is clearly superior to all conventional construction methods in all these factors. In addition, binderholz construction solutions offer high quality with comparatively low expenditures in terms of building time and costs.

Moreover, binderholz produces in accordance with the zero-waste principle. This means the raw material of wood is 100% utilized, with largely climate-neutral methods. It begins with conservative wood harvesting from sustainably managed forests and ends with a broad range of solid timber products on offer. All by-products accumulated in production are completely utilized. They are converted into green energy in proprietary biomass combined heat and power stations or for the production of biofuels. Furthermore, binderholz construction solutions feature a high degree of recoverability; at the end of their useful life, they can be 100% ecologically recycled. Thus binderholz ensures a conservative and intelligent use of the raw material of wood.

Natural

As natural wood is used without building chemistry in solid timber construction, a building construction of solid timber has even positive effects on health. Cheap building materials and furniture can release problematic substances possibly causing allergies and other illnesses. To deliberately counteract the causation of such diseases, it should be relied upon materials that are harmless in terms of building biology. Solid timber is a completely unpolluted building material and moreover even strengthens the immune system and vitalises the nervous system. Wooden rooms have a calming effect and ensure a pleasant room climate.

Sustainability

Sustainability rests on three pillars: an economic, an ecological and a social pillar. All three of them must be in harmony before it can be spoken of sustainability. Building with wood fulfils all of them. Building with wood is economical. Building with wood is ecological because wood is a sustainable raw material. And building with wood is socially valuable because wooden structures are optimised energetically and therefore affordable over the long term.

Wood is a renewable raw material with a positive effect on the environmental climate. During their growth, trees convert CO2 and water into hydrogen. When wood is used as building material, it serves for many years as a safe CO2 store. Each cubic metre of wood that is used as substitute for other building materials, reduces the CO2 emissions in the atmosphere by 1.1 tonnes on average.

Pre-fabrication

Wooden building elements are nearly completely pre-fabricated (see Figure). This results in advantages of quality and scheduling. Even humidity and temperature is prevalent in the production halls. The assemblers work under steady framework conditions and the structures are protected from the effects of weather. The work in subsequent trades, such as electrical and sanitary installations, is prepared to the furthest extent so that the construction progress at the construction site proceeds in a coordinated and swift manner.

Efficiency

The low deadweight of timber and dry construction structures reduces the expense for the foundation and baseplates. The high degree of pre-fabrication simplifies the implementation at the construction site and secures a standardised and verifiable level of quality. The construction site equipment can be reduced and the logistics expense is lower. The dry construction design shortens the construction periods significantly and thereby enables that the buildings can be used at an earlier point in time, which in turn drastically reduces the financing periods.

Savings of time

The savings of time through the use of binderholz CLT BBS can be substantial in the construction of large-volume buildings. The high degree of pre-fabrication drastically shortens the construction phase. Load-bearing wall elements simply need to be aligned and linked to each other. Based on their comparably low weight, these pre-fabricated timber elements can have very large dimensions. As the installation is made in the level between the plasterboard system and the timber element, the subsequent cutting and plastering work is omitted.

Long lifetime and value preservation

Long tradition in crafts and industry as well as targeted research and development have generated the experience to use the right product in the suitable manner for the various applications. Austrian institutions and businesses are internationally leading in the production and further development of wood and timber materials, and in state-of-the-art production and processing techniques. In modern timber construction, all businesses that manufacture self-contained wall and ceiling elements are subject to internal and external supervision. Moreover, many businesses are voluntary members of workmanship and quality associations. The quality of the used timber materials and products is ensured by means of defined standards and permits. If wood is used professionally (constructive wood protection), it has a long lifetime and its value is preserved.

Stability and light-weight

Wood stands out for its very high static quality. In reference to its deadweight, wood carries 14 times as much as steel; its pressure resistance equals that of reinforced concrete. Multi-story wooden buildings and wide-area load-bearing structures are optimal areas of use. The reason for the high stability is the microstructure of wood, which ensures high load-resistance with simultaneously low deadweight. Wood is therefore a light-weight building material with excellent technical characteristics. In spite of its low weight, wood offers high tensile and pressure resistance and it is resilient to weathering when it is used correctly.

More net useable area by virtue of narrower wall structures

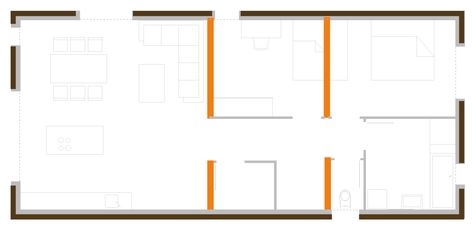

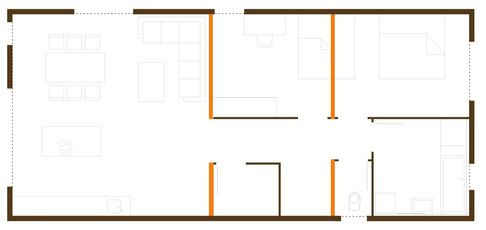

Wood has excellent heat insulating characteristics, which is why substantially leaner walls than in conventional construction can be incorporated in solid timber buildings. For example, the portion of walls in timber construction adds up to merely 20% of the constructed overall floor space, while this portion is greater in conventional buildings (see Figures). This means that up to 10% more residential space can be had in a building made of wood with the same exterior dimensions as a conventional building. In the case of a single-family home this means a gain of floor space of almost an entire room. For larger projects, this outstanding construction feature of wood also has positive effects on the construction density. Significantly less land is needed for high-quality residential buildings. Thus, also the cost share for land is reduced for all involved. Building with wood creates more living space.

Floor plan of a flat in the conventional construction style - Residential floor space of 100 m²

Floor plan of a flat in the timber construction design - Residential floor space of 110 m²

Noise-free, dust-free, rainproof

Noise, waste and dust are three keywords that probably everyone associates with construction projects. Not so when building with CLT BBS. Based on the high degree of pre-fabrication and the installation method of solid timber, CLT BBS in particular, noise, waste and dust can be reduced drastically. The installation of CLT BBS does not require a noisy machine park, as individual elements are merely bolted together on site. A raised level of pre-fabrication of the CLT BBS elements reduces the processing steps on site and lowers the exposure to dust, waste and also noise. Since timber does not require any periods for drying and as the construction site is rainproof when the roof is set on top, also multi-storey floor additions can be realised quickly within a few days.

Photos: ©DasPosthotel GmbH, FG & SG, binderholz