Water Park Rulantica, Rust | Germany

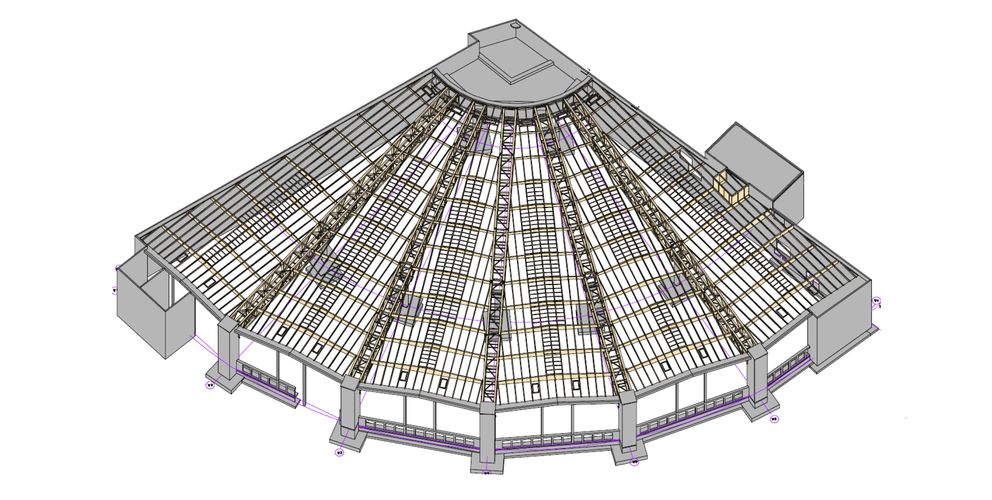

The new Rulantica water park in Europa-Park Rust is one of the most extensive individual investments of a private company in the region as well as in the almost 240-year history of the Mack family, being a Nordic-themed experience world that did not yet exist in Europe. The area on which the new water world was built corresponds to around 63 football pitches. A mix of Scandinavian style, Nordic countryside features as well as imaginative designs, and all of those framed with a binderholz glulam roof construction.

Facts

Project Roofing of the water park Rulantica

Ort Rust, Germany

Year of construction 2019

Construction costs approx.180 million Euro

Builder Europa-Park Freizeit- und Familienpark Mack KG

Architecture pbr Planungsbüro Rohling AG

Wood construction Holzbau Amann GmbH

Net area 32.600m²

Gross building volume 305.000m³

Material use 1.100m³ glulam GLT und 300 m³ binderholz CLT BBS

Construction

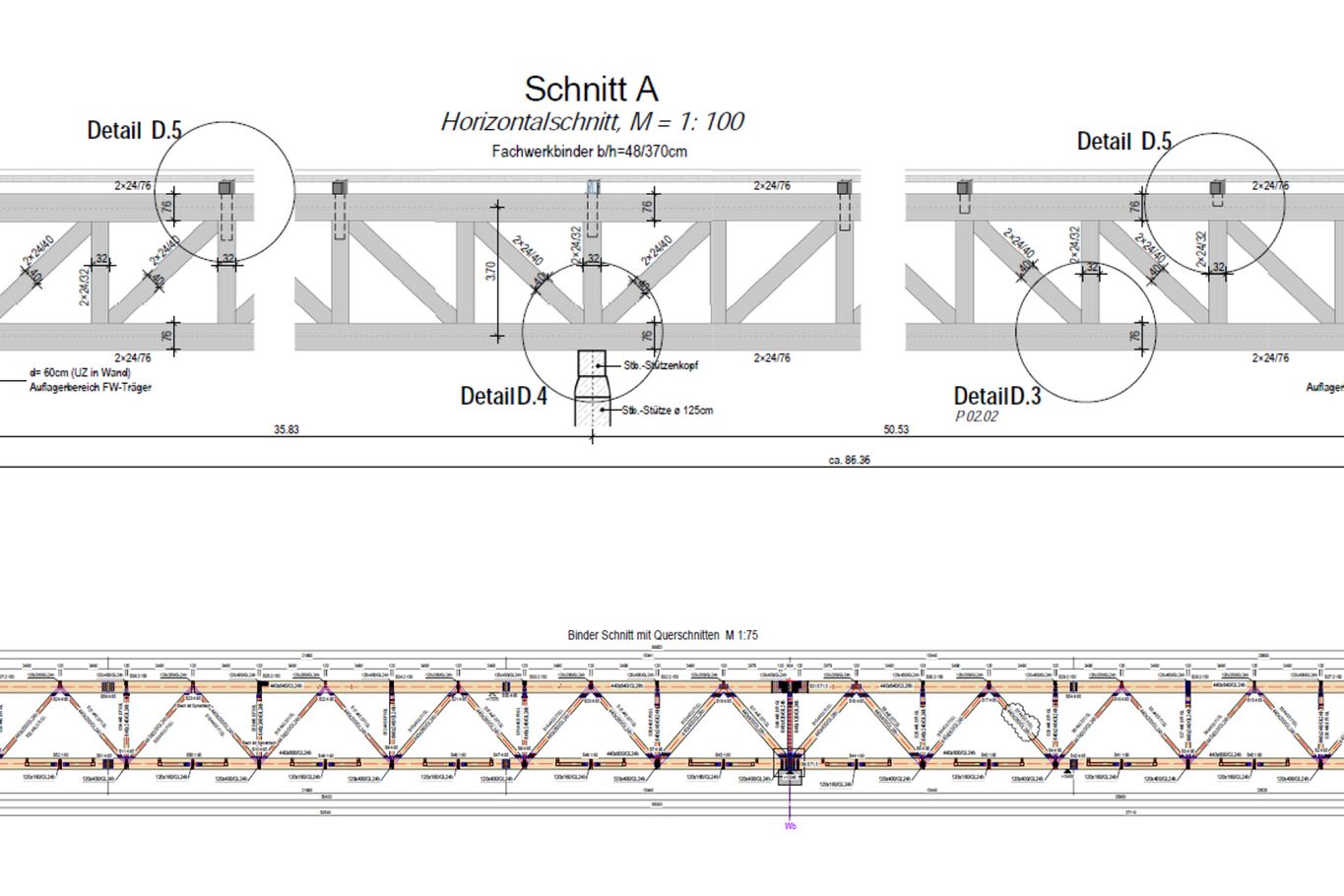

The structural heart of the water world is a shell-shaped hall with a height of 20 m and a usable area of around 12.000 m² , of which around 3,000 m² are water pools. More than 1.000 project participants from around 40 trades were ultimately responsible for the successful completion of the complex construction project. The wooden roof consists of five 86,50 m long wooden framework boxes with a height of around 4,80 m and a width of 3,84 m. Integrated within these cross-sections are huge ventilation ducts for the fresh air supply of the hall.

Between the wooden framework boxes, 66 saddle roof beams made of glulam are hung at a distance of more than 7 m. Their span increases continuously from 6 m to 30 m. Across to the saddle roof ties stretch binderholz CLT BBS elements nailed upon glulam stringers, as two-span beams or three-span beams with staggered butt joints. Connected to a disc, they provide horizontal stiffening.

Planning and implementation

After the conceptual idea of the roof structure was decided, the service contract was put out to tender. A functional description was produced, which included all the architectural plans as well as a preliminary structural engineering calculation prepared by the engineering office. In addition to pure wood constructions, variants made of wood-steel framework beams were also offered as hybrid constructions. In order to avoid cost-intensive surface scaffolding in the hall area, the acoustically effective under-ceiling was already installed in the shell construction phase and mounted with the binderholz CLT BBS. The required emergency sealing was equally regarded as a steam barrier for the later roof construction. The construction time of this project was about 24 months.

Logistics, assembly

The assembly of the main belts of the wooden framework boxes with a dimension of 44 x 60 cm was carried out on site on the ground. At the same time, the machining at Holzbau Amann was completed “just in time”. The glulam was supplied by binderholz, machined and delivered to the construction site, already prepared for construction with slotted sheets. Every week, about three to four trucks with prefabricated material drove from the factory to the construction site. There, the elements were assembled and screwed together with all the belts, beams, diagonals and posts by a team of six carpenters.

Photos: © Holzbau Amann GmbH

Plans: © Holzbau Amann GmbH

Video: © parkerlebnis.de