Quartier Prinz-Eugen-Park, Munich | Germany

The largest contiguous timber construction settlement in Europe with around 600 apartments in wood or wood hybrid construction has been created in the district of Oberföhring. Different building types up to 7-storey apartment buildings were built from wood. The approximately 30 hectares large site of the former Prinz Eugen Barracks is located in city district 13 - Bogenhausen. The apartments have been built by building associations, cooperatives, urban and independent developers and covers a wide range of housing needs: for rent and property, in different types of buildings, for all household sizes and income groups and alternative forms of housing.

FACTS

Project City quarter - new building with 600 apartments

Location Munich, Germany

Construction 2020

Client City of Munich

Architects Atelier 5 Biel, AGMM München, dressler mayerhofer rössler architekten, H2R Architekten, Kaden und Lager, Rapp Architekten

Builders Bürgerbauverein München BbvM eG, Der Kleine Prinz Gbr, Gemeinsam Größer GBR, GWG München, München GBR, WOGENO

Execution Gumpp und Maier mit Zimmerei Vorholz Hawran, Huber und Sohn, Lignoalp, Müllerblaustein, Renggli International

Material use 5,000 m³ binderholz CLT BBS

Timber building projects of 8 planning offices

The designs of the wooden settlement encompass eight individual timber building projects. They have been implemented by the municipal housing associations GEWOFAG and GWG, four building associations and two cooperatives. Part of the apartments are 452 subsidised or privately financed rental apartments. The rest are owner-occupied condominiums of the building communities. In six of the eight construction areas, the residential buildings were built in solid wood construction from binderholz CLT BBS.

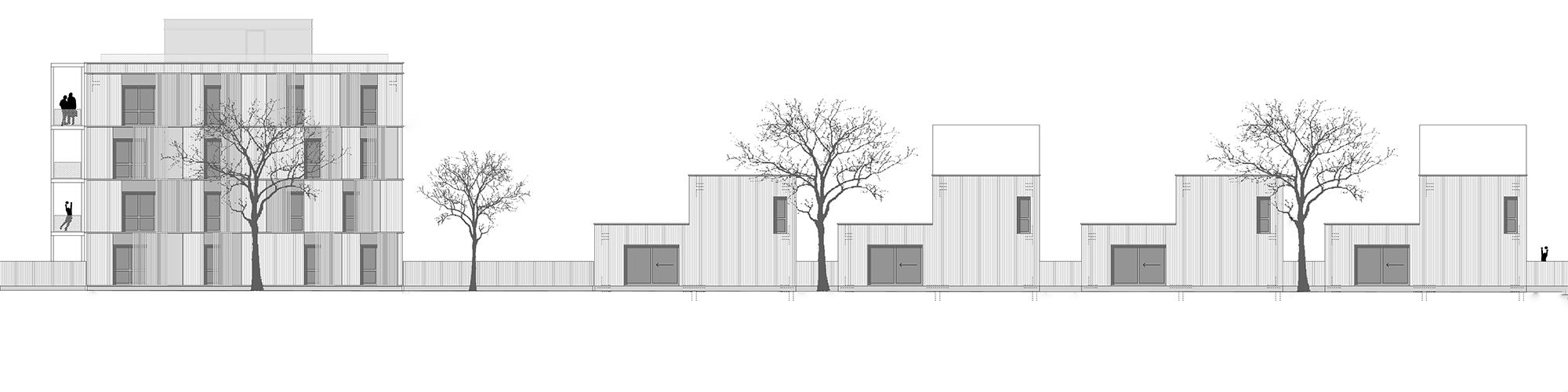

Integrated into the residential quarter are, among other things, two childcare centres, a district headquarters, a covered market square and a café. There is also plenty of space for community-oriented uses, such as workshops, co-working spaces, common areas, shared rooftop gardens and urban gardening areas. The buildings, which are up to seven storeys high, are built in various construction methods, from wood hybrid construction to pure timber construction.

An ecological model settlement

The projects in Prinz-Eugen-Park were intended to represent an ecological approach through conscious use of resources. For example, renewable and sustainable raw materials such as wood were mainly used for the buildings. In the south of the Prinz-Eugen-Park an ecological model settlement was built with around 450 apartments, which are divided into different building types in wooden construction. This enabled the city of Munich to set new standards in timber construction, as the Prinz-Eugen-Park is currently the largest contiguous timber construction settlement in Europe. The new ecological urban district will also be completed by offers such as car sharing, flexible parking management or charging stations for electric bicycles and electric cars.

In addition to the usual apartment buildings, also terraced houses, town villas and point houses were built on the site. Only 64,000 of the 195,000 m² floor space have been allocated to Gewofag, which has built, among other things, two day-care centres with space for 110 children as well as accommodation for three outpatient assisted living groups of physically handicapped children and adolescents. 5,280 m² of the planning area have been allocated to GWG Munich for residential apartments. In addition, the social institution "Haus für Kinder" (House for Children) has been integrated on an area of 1,180 m².

The high wood content of the buildings contributes significantly to climate protection. In total, about 13,000 tons of carbon dioxide are stored in the long term. Compared to the mineral construction method, depending on the wood content, the wood construction can replace between 30 and 60% of the climate-damaging emissions. The timber construction thus makes a positive contribution to climate protection.

With the numerous wooden buildings in the Prinz-Eugen-Park, the city of Munich has created an ecological model settlement for climate-friendly construction with wood. In the construction industry, the raw materials steel and concrete dominated for a very long time. It was only through climate change that the natural building material wood has regained its importance and has been experiencing an economic boom ever since. A clear, positive conclusion for our climate balance. The entire planning and implementation were strictly based on the ecological criteria catalogue of the state capital Munich. With this timber construction settlement, the city wanted to set up a milestone for climate-friendly urban construction in the future.

binderholz products were used for a total of six construction sites. The building types were constructed with wooden frame walls and solid wood ceilings made of binderholz CLT BBS. Dimensioning and element construction vary for static, structural or fire protection reasons. The stairwells are designed in reinforced concrete and the point building structure develops around them. The façade is characterized by a pre-greyed, vertical wooden formwork emphasising the chosen construction method in wood. The point buildings feature a slightly protruding perforated façade which determines their appearance together with the external, coloured sun protection elements.

...and everything made of wood

The walls of the insulated frame construction are encased with pre-greyed, vertical spruce formwork. Inside, visible solid wood ceilings, wooden floors and wooden stairs create a homely atmosphere which is typical for wood. Already when applying for the land, the builders committed to use renewable raw materials for a high proportion of the structures. As a basis for the decision which materials should be used for the components, the exact proportion of renewable raw materials was calculated by means of a separate calculation method in the preliminary design phase, in order to achieve the required kg/WF ratio of renewable raw materials.

Highly heat-insulated wooden buildings

In the atrium buildings, the entrance zones are cladded with striking, lamella-like, vertically placed battens. The buildings are designed as the denominated KFW Effizienzhaus 55 (as of 2014). A well-insulated building envelope made of highly thermally insulated wooden frame elements and triple-glazed wood-aluminium windows not only create good conditions for low transmission heat losses, but also for low heating energy requirements.

Quality assurance of wood construction

The quality assurance of the wood construction is guaranteed by a consulting concept. The builders have committed to an integrated planning approach with all the experts and companies involved in the planning and implementation of the project. As a result, the main advantages of the wood construction method, such as a shortened construction time, cost reliability and the desired execution quality, can be realised. It was also stipulated that the wooden building materials must come from sustainable forestry management in the region. A specifically set up advisory panel with four recognised experts also advised on fire and sound insulation as well as statics in multi-storey wood construction.

Awards

5th Rosenheimer Holzbaupreis 2020

The competition for quality wooden buildings with a high architectural value in the region has been held with great success since 2006.

Photos: © binderholz © Ulf Rössler © Markus Dobmeier © dressler mayerhofer roessler architekten © Conné van d‘Grachten © GSP Architekten

Video: © binderholz