INTRO, Cleveland | USA

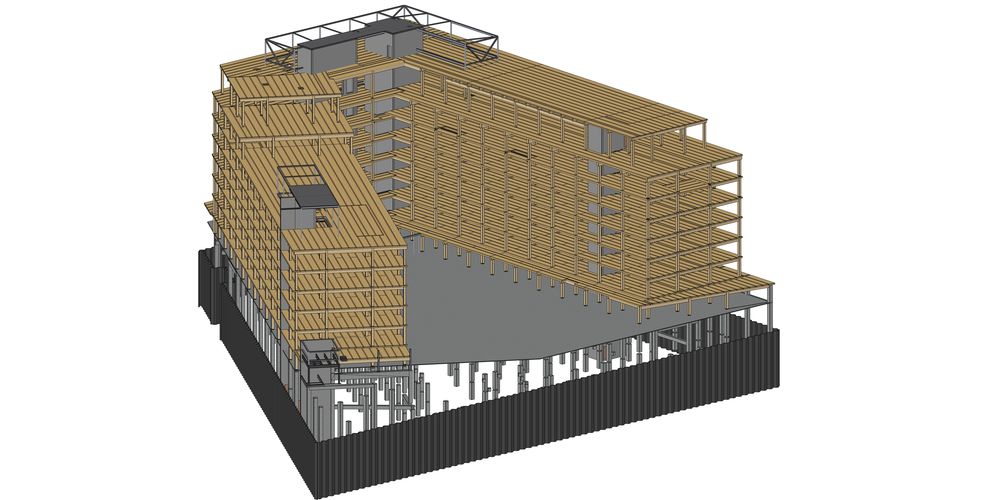

Boasting 297 living units thereof 10 penthouses, the 9-storey residential building and integrated shopping centre was built in Cleveland, Ohio, marking the largest solid wood construction project in the U.S. A total of 5,650 m³ of binderholz CLT BBS and 1,500 m³ of glulam from sustainable forestry were used. The entire transport of the solid wood elements was realised by rail from the production plants to the port of Amsterdam. The elements were then shipped directly to the port of Cleveland via the Atlantic Ocean and the St. Lawrence River on a so-called break bulk ship.

Facts

Project 9-storey residential building with integrated shopping centre

Place Cleveland, Ohio, USA

Completion August 2022

Client Harbor Bay

Architecture Hartshorne Plunkard Architecture

Execution Seagate Mass Timber Inc.

Structural Engineering Forefront Structural Engineers

Mass Timber Engineering Fast + Epp

Material use 5,650 m³ binderholz BBS, 1,500 m³ glulam

A new sustainability standard

Located opposite the historic West Side Market, the 47,000-m² building was officially opened in August of 2022, following 2 years of construction. At the same time, the project received a LEED Gold Certificate for ecological construction. After all, the largest solid wood construction project in the U.S. releases 21 % less CO2 than an equivalent steel or concrete building, setting a new sustainability standard.

Modern, premium solid wood complex

The modern, premium solid wood complex boasts 3,252 m² of retail space, an impressive event space on the roof as well as approx. half a hectare of public green space. The flats are characterised by contemporary interior design with exposed solid wood ceilings made of binderholz CLT BBS. The fitness centre and pool on the roof offer residents great views of the city. Additionally, there are three restaurant concepts, among which a café, a pub and an upscale restaurant.

Eight out of the nine stories on top of a single-storey ground floor made of concrete under which an underground car park is located, were made of solid wood. Almost half of the building's interior space consists of exposed wood, using binderholz glulam beams and supports as well as binderholz BBS floors and ceilings.

The BBS used is technically approved for use on the U.S. market as per technical approval ICC-ES ESR-4081. This was developed in collaboration with Holzforschung Austria, the ICC Evaluation Service, LLC (ICC-ES) and the Pacific Lumber Inspection Bureau (PLIB), with binderholz being the first European cross-laminated timber manufacturer to receive approval for the U.S. market.

"Inside, the wood is bright, beautiful, clean and modern," says Dan Whalen, Harbor Bay's vice president of design and development. "It has a high-end aesthetic and creates a calming feeling that is certainly different from any other building in Cleveland."

First USA break bulk deliveries for CLT BBS and glulam

The transport of the solid wood elements for the project was the first break bulk delivery from the binderholz production plants in Austria and Germany overseas, directly to the port of Cleveland. In order to demonstrate the most positive ecological balance possible, the delivery from the BBS plants to the port of loading was carried out by rail transport. This made it possible to act even more ecologically, efficiently and quickly with the binderholz solid wood products CLT BBS and glulam in the USA.

Photos: © binderholz © Harbor Bay © Seagate Mass Timber

Renderings: © binderholz © Harbor Bay

Video: © binderholz