Coffee Production Plant Johannson, Vestby | Norway

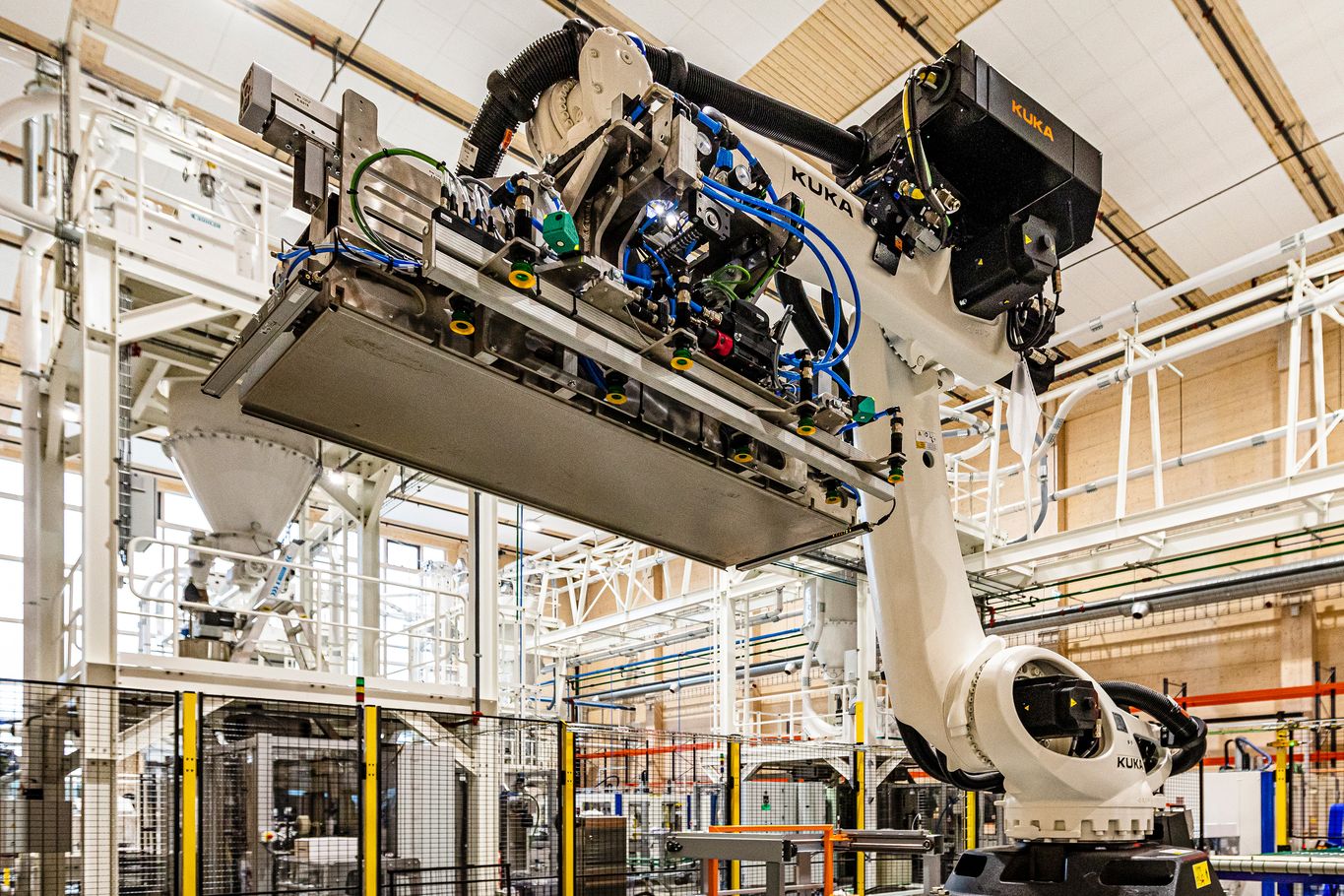

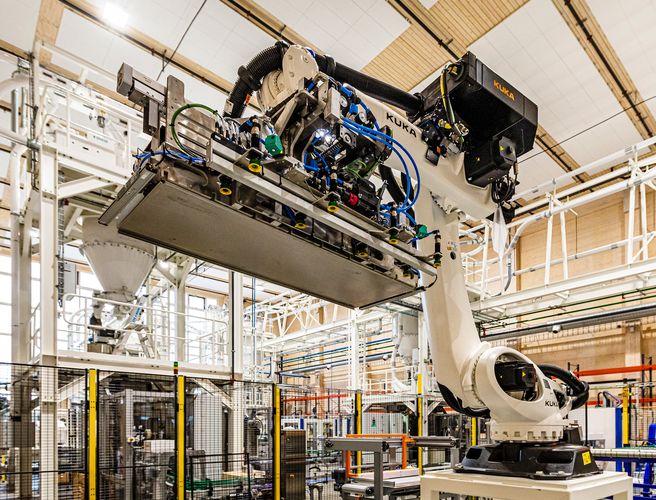

In the 9,450 square metre coffee processing plant, it smells not only of freshly roasted coffee beans, but also of wood. The new production facility of Joh. Johannson Kaffe AS is capable to roast, ground and pack 70 to 80 tons of best quality coffee beans of the brands Ali Kaffe, Evergood and a few others every day. The new solid wood industrial building has been awarded the BREEAM certificate.

FACTS

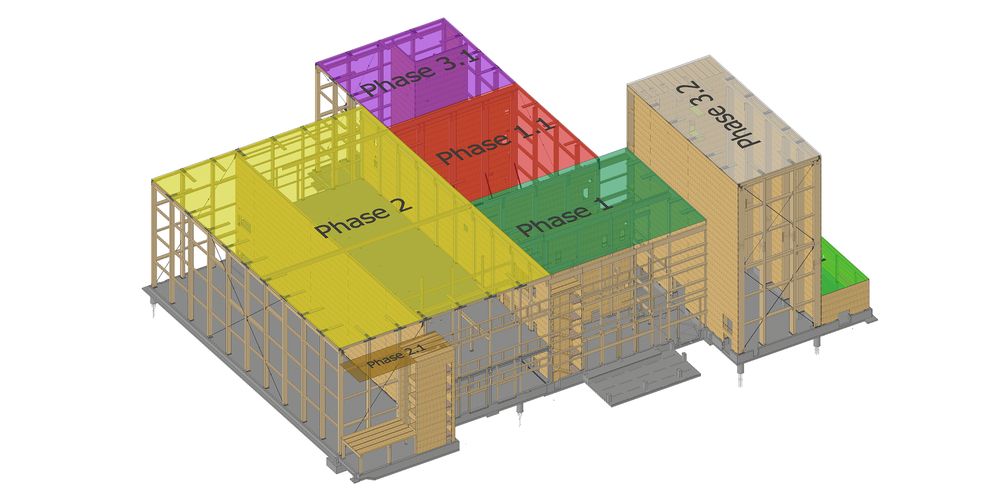

Project Newly constructed industrial building for coffee production

Location Vestby, Norway

Year of construction 2019

Client Joh. Johannson Kaffe AS

Architects Arkitektene Astrup og Hellern

Execution AF Gruppen Norge AS

Usable area 9,450 m²

Products Use 1,100 m³ binderholz CLT BBS and 1,300 m³ glulam GLT

Record high in Norway for solid wood buildings

The aroma of fresh coffee is highly appreciated by the Norwegians. In a global comparison of coffee consumption, they are just second after Finland as the frontrunner. The construction of a state-of-the-art coffee production facility therefore seems natural. This facility can process 12,000 tons of coffee per year. The new building also includes office, warehouse, packaging and sales areas.

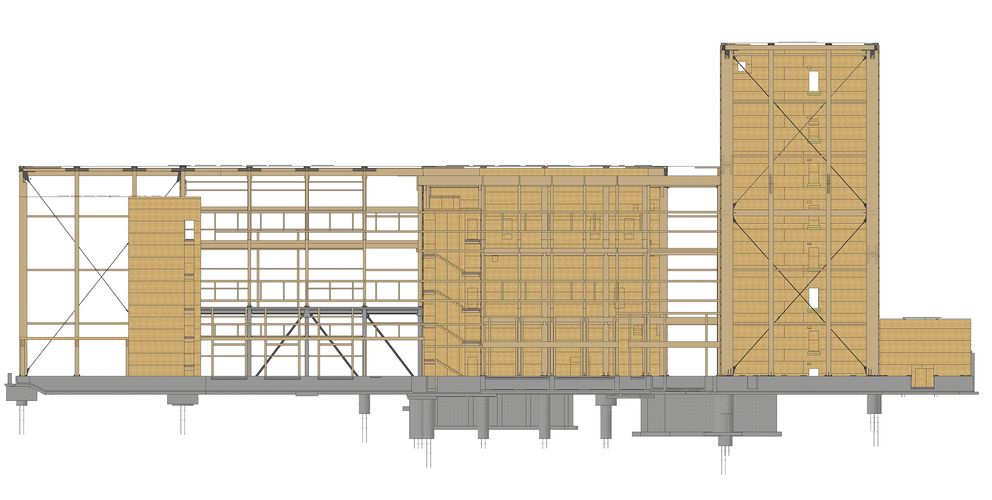

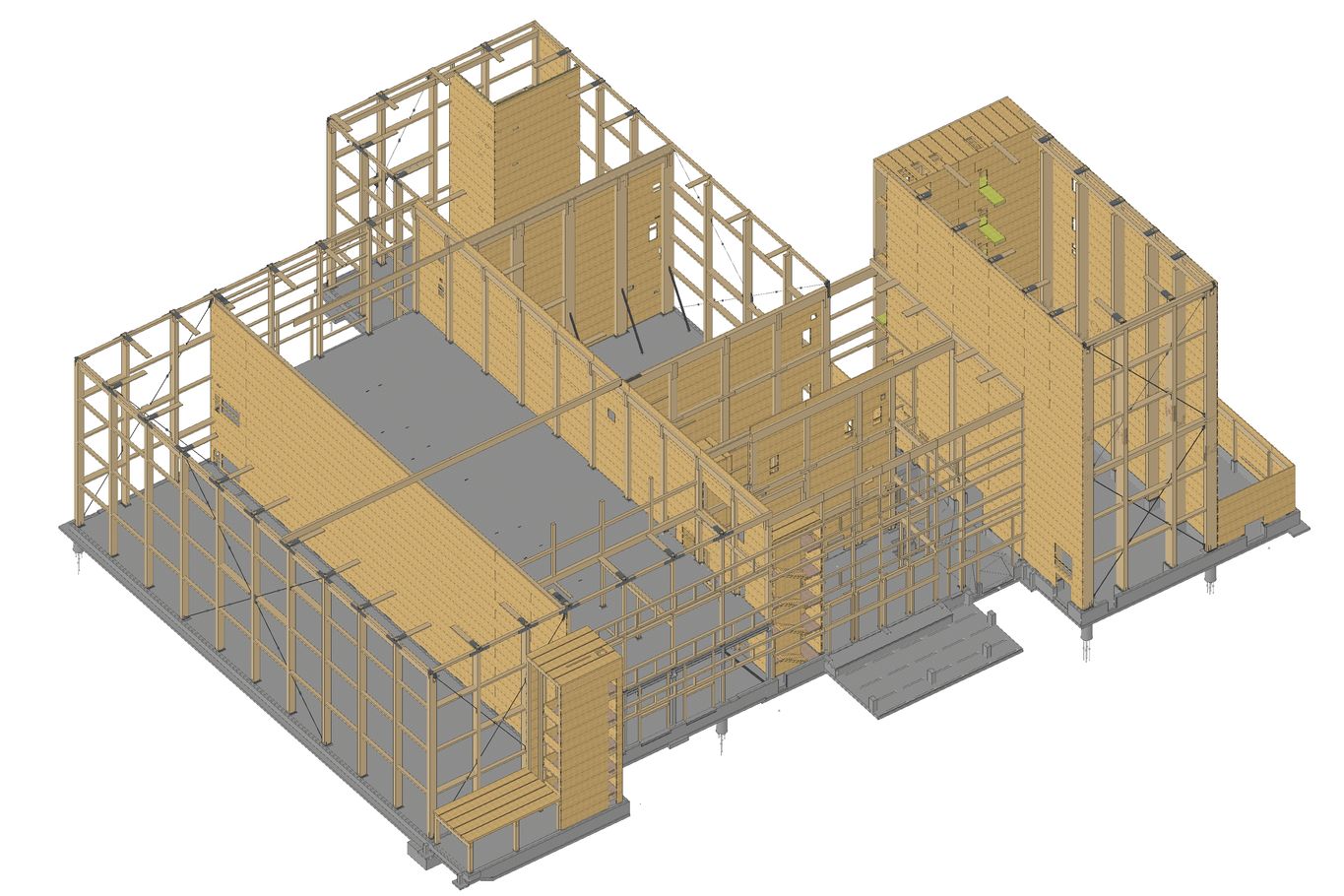

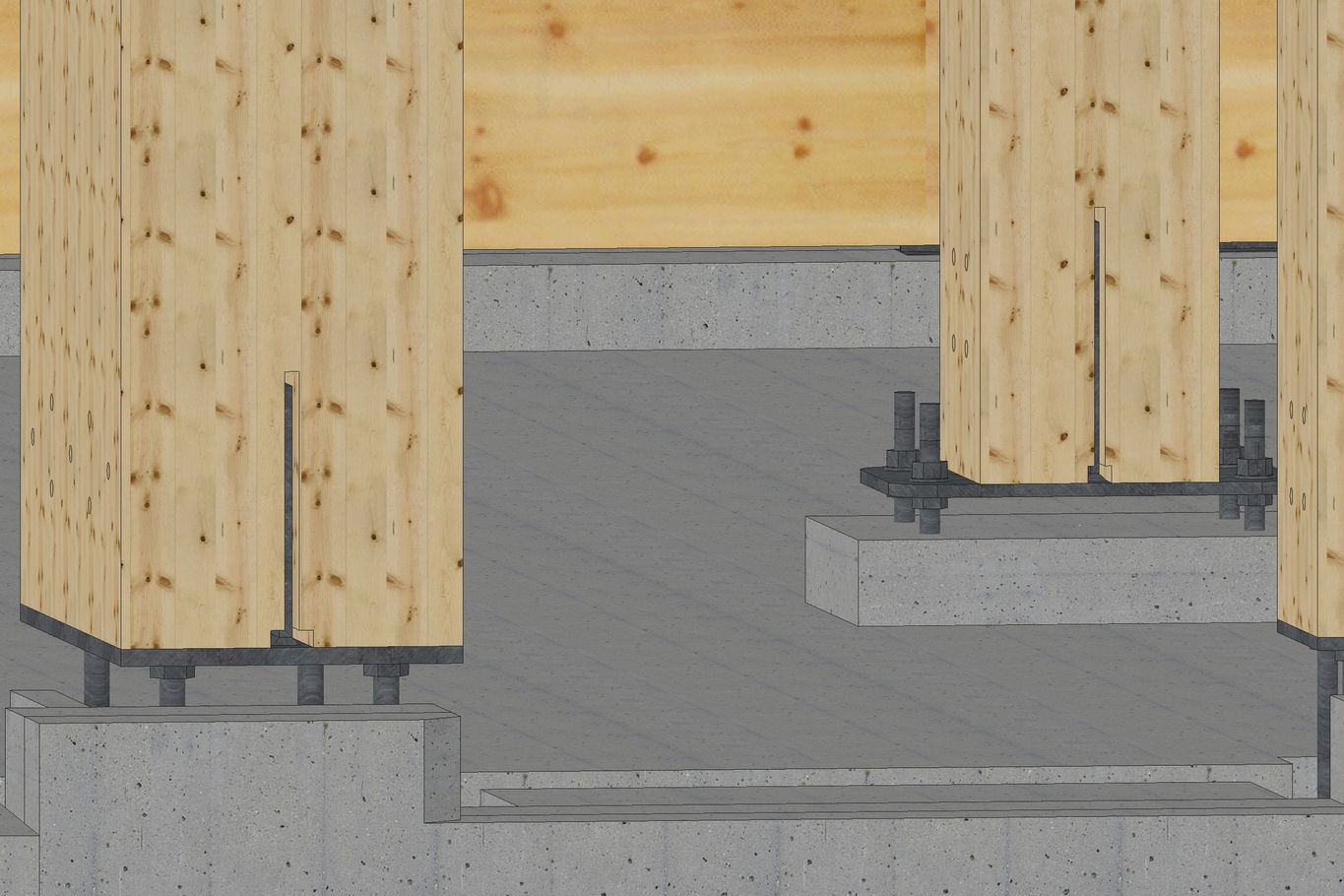

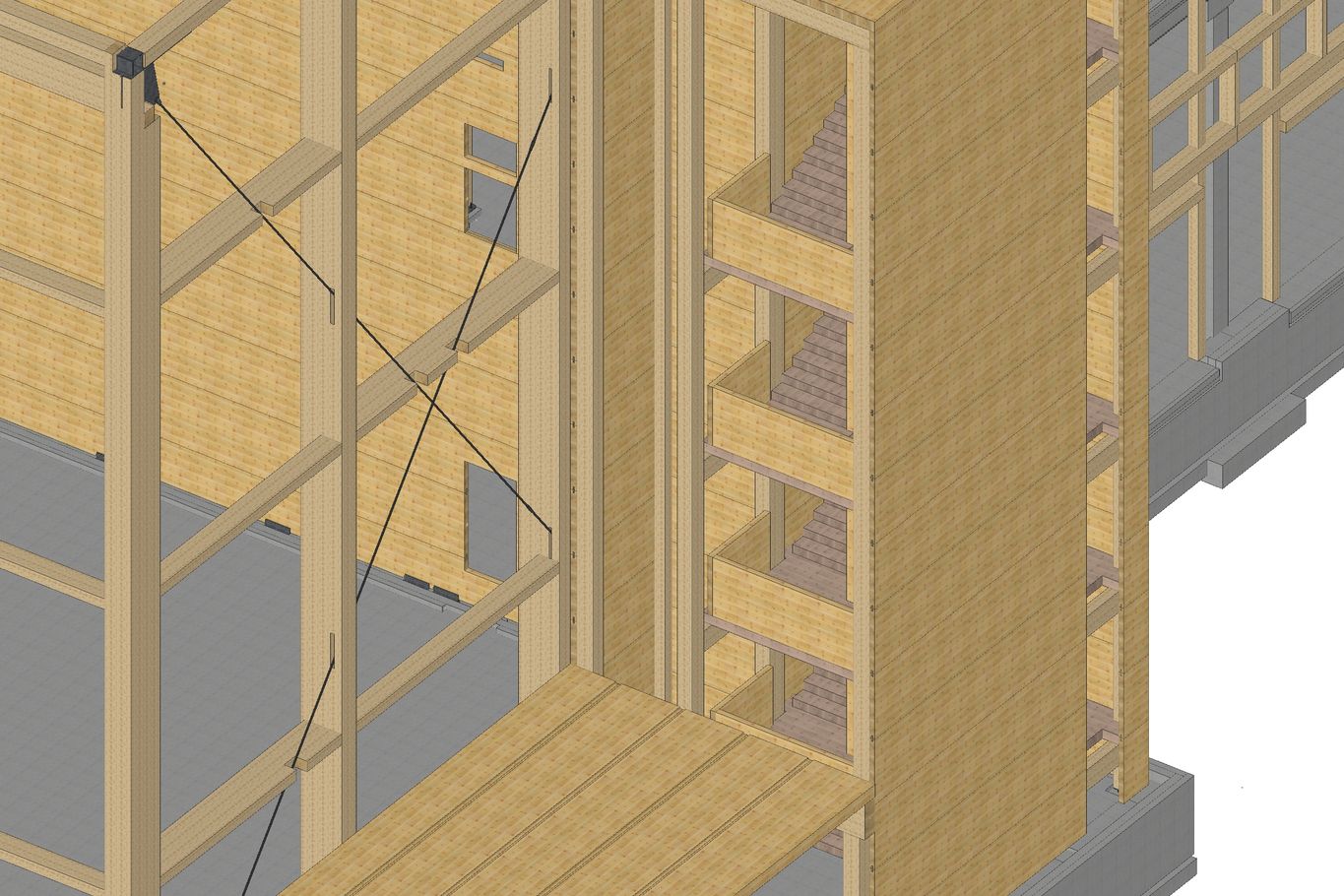

Some parts of the building have three floors due to the height of the production facilities, while other parts of the building are only single-floored. At its highest point, the building measures 35 metres. Wood is the main material both inside and outside. The walls and ceilings are made of binderholz CLT BBS, while glulam was used for struts and girders. As this industrial building contains large production equipment, it was important to avoid disruptive struts indoors as far as possible. For this reason, the choice was made for a cantilevered roof construction made of wood. Only the floor and some struts on the ground floor were made from concrete for stabilising and to carry the heaviest load of the building. In addition to the stairs, the elevator shaft inside is made entirely of binderholz solid wood products. For fire protection reasons, it is additionally covered with plasterboard. Pine wood was used for the façade.

Engineering services of binderholz

In addition to the supply of solid wood products, binderholz was also commissioned with the structural calculation, production modelling, the production of assembly plans, the calculation and delivery of fastening materials as well as the supervision on site.

“This is a new ground-breaking piece of work, both for the consultants and for us. A lot of schools and houses are built of solid wood, but we haven't built any large industrial buildings yet,” said Trond Segerblad, the construction manager.

BREEAM certification for excellent environmental profile

The project is a new building needed due to the relocation of production. Joh. Johannson Kaffe AS produced so far in its factory in Filipstad. About 40% of the coffee consumed in Norway comes from this company’s production. With the new solid wood building and the state-of-the-art production facility, CO2 emissions can be reduced by 85% compared to the old production facility. The heat generated during the coffee roasting process is used to heat the building. The energy supply is provided by an earth-heat pump as well as by a large photovoltaic system with 1,280 solar cells situated on the façade and solar panels on the roof. Biogas and the heat recovery process make further energy usable.

Thanks to the intelligent use of ‘green energy’ and the resulting excellent environmental profile, the Johannson coffee production building has received the BREEAM certification ‘Excellent’.

“We are very satisfied with the result. The aim was to build the most modern and environmentally friendly coffee roasting facility in Europe, which will last for at least 60 years,” says the client.

Other awards

The Norsk Energi trade association has awarded the company the energy and environmental recognition ‘EMIL Prize 2019’. This award recognises individuals, companies or institutions that are particularly exemplary in terms of environmental protection and implement energy-saving measures. Norsk Energi praises that Joh. Johannson Kaffe AS takes the climatic challenges seriously and minimizes energy consumption as well as CO2 emissions through solid wood construction and the use of state-of-the-art production facilities.

EMIL Prize 2019 awarded to the company Joh. Johannson Kaffe AS

Photos: © binderholz, © JOH-SALG AS

Rendering: © binderholz