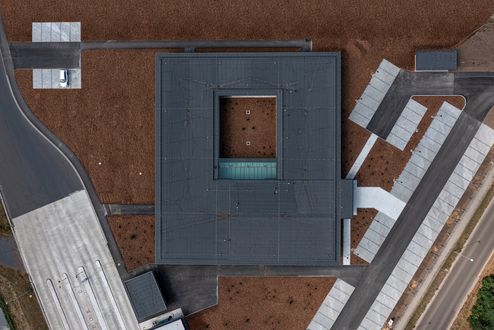

binderholz office building in Baruth | Germany

Due to the binderholz Group's continuously growing number of employees, a state-of-the-art office building was required at its Baruth site. The single-storey building with an atrium on the inside wows with its clean structure, with its 1,700 m² of usable area offering space for 72 employees. The modern training room is equipped for up to 30 people and features a variety of meeting options for all requirements. On top of that, the building pampers its users with a comfortable cafeteria with outside area. Apart from spatial advantages, the new building also boasts a number of ecological and economic factors.

Facts

Project Cost-efficient and future-oriented office building

Location Baruth, Germany

Completion 2021

Architecture / Design Architectural Office Spitzner

Execution MHB - Holz und Bau

Technical Design TGA IB-Krallinger

Material use 715 m³ binderholz CLT BBS, 15 m³ glulam GLT and 300 m² 3 layer solid wood panels made from spruce and pine

Wall construction | Ingeniously simple, simply ingenious

The single-storey building features a straight-forward layout characterised by efficient partitioning. The load-bearing exterior walls were made using so-called binderholz CLT BBS thermal elements. These BBS Thermo walls were constructed from 27.5-cm-thick binderholz CLT BBS without any additional thermal insulation. The wood surface of all load-bearing components was finished in residential visible quality. On the building’s interior, visible surfaces consist of spruce that was partially stained in white, on the exterior they are made from local pine sourced from the Baruth sawmill. Measurements taken in our other office rooms that were built with the same wall structures show that the ‘single material’ property of these walls has a positive effect on the building’s energy balance.

Implementation

The new single-storey building houses many modern offices, two spacious seminar rooms as well as several meeting rooms. The building had been designed in just 16 weeks, which included technical design for its mechanical, electrical and plumbing equipment which was considered at a very high level of detail (wood processing specifications, slots, breakthroughs and much more). From the beginning of timber construction to the completed, rainproof flat roof, the carpenters only needed 21 workdays.

A total of 715 m³ of binderholz CLT BBS were needed to construct the new office building. A further 15 m³ of glulam GLT and 300 m² of 3 layer spruce and pine panels went into the new building.

This schedule was only made possible by well-oiled teamwork. Design as well as timber construction statics were taken care of by the binderholz construction systems team from Hallein while many binderholz employees from various locations were involved in its realisation. The entire design concept is based on the binderholz CLT BBS 125 grid. This specification enabled us to optimally utilise the material and thus construct very cost-efficiently. A total of 715 m³ of BBS 125 elements were installed. The solid wood products were supplied to Baruth by our production sites in Austria and Germany.

Unique material features

CLT BBS has a monolithic structure which means it is basically “a single piece of wood”, with only 0.6 % of ecologically harmless glue. This solid prefabricated part can bear heavy loads, is fireproof, can be installed quickly and in dry condition and has noise and thermal insulation properties to boot. It contributes to the regulation of the indoor humidity, thus creating a cosy and balanced indoor climate in the summer and winter alike. binderholz is convinced that constructions using the so-called CLT BBS Thermo walls (a solid cross laminated timber construction without additional thermal insulation layer but an outside pine layer to structurally protect the façade) have particularly high future potential. These solid wood structures make full use of the single material philosophy. CLT BBS Thermo walls combine the proven technical benefits of solid construction with the ecological advantages of the sustainable resource that is wood.

Fully convinced of this method's material and construction properties, binderholz has already constructed four administration buildings with CLT BBS Thermo walls:the administration building of Binderholz Kösching GmbH / Germany (276 mm CLT BBS Thermo wall), the administration building of Binderholz Unternberg GmbH / Austria (200 mm CLT BBS Thermo wall), the administration building of Binderholz Nordic Oy in Lieksa / Finland (234 mm CLT BBS Thermo wall) as well as the administration building of Binderholz Bausysteme GmbH in Hallein / Austria (234 mm CLT BBS Thermo wall). In these buildings, very positive experiences have been made with the CLT BBS Thermo wall product so far, especially with regard to the heating and cooling energy consumption as well as the material's effect on the indoor climate.

The heating system

The building is supplied with heat by our own biomass heating plant complete with heat exchanger which was installed in the utility room. Heating works by means of low-temperature surface heating systems, which were mounted to the office ceilings. The building is cooled by a system using ground water.

The heat is dissipated via the heating/cooling ceiling system (gentle cooling) and transferred to the groundwater via a separating heat exchanger = 100 % free cooling. The required fresh air is pre-conditioned (cooled/heated) and brought in via a ventilation and air-conditioning system; it is also supplied via the biomass heating plant available in the factory or the groundwater.

Photos: © www.florianhammerich.com