Road maintenance depot, Haiming | Austria

The largest and, at the same time, the most modern road maintenance depot has been constructed in the municipality of Haiming in the Upper Oetz Valley. From October 2016 onwards, a total of 185 kilometres of highway will be maintained from Haiming.

Within the Imst District Building Office, the existing four road maintenance depots in the districts of Imst and Landeck will be combined at three sites. In the course of this, the Umhausen and Nassereith road maintenance departments in the Upper Oetz Valley will be combined at the new Haiming road maintenance depot. The site was selected as it represents an ideal base for the entire district.

The new depot employs 32 people. The 9,000 m² premises will house offices, staff and recreation rooms as well as woodworking and metalworking workshops. The site also has space for garages for trucks, Unimogs, loaders, tractors and small vans. The warehouse is designed to store other equipment, traffic signs, road block materials and other materials. The construction costs amounted to around €5.5 million. It is extremely positive that all the construction contracts were awarded to Tyrolean companies.

facts

Project Vehicle sheds and office building

Place Haiming, Austria

Year of construction 2016

Client Federal state of Tyrol

Execution of timber construction Maurer+Wallnöfer GmbH & CoKG

Architecture DI Karin Kopecky

Support structure planning tragwerkspartner zt gmbh

Decision to use wood

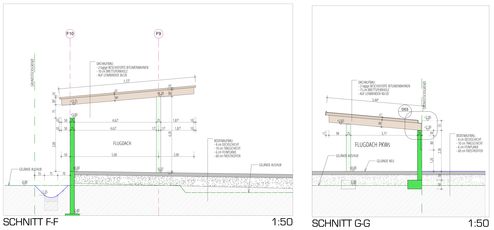

Statement by the architect Karin Kopecky: “It rapidly became clear why we opted for wood. One of the main reasons was its fast assembly and the resulting early occupation and use by the client. The material does not need any drying time, as is the case with concrete construction, and there is no residual moisture in the building that first has to dry out. Moreover, with the large span, the beams could only be designed to be slimline in wood. A steel or other metal design was impossible due to the particular effect on the machines and vehicles caused by the high salt content in the air. Designing a purely industrial building in wood creates a certain degree of comfort and a more pleasant atmosphere, which has a very positive effective on the workforce.”

Flexible use of this road maintenance department is easy for the workers. Changes, openings, assembly of various elements, shelves etc. can all be easily and quickly done with minimal effort.

Use of materials

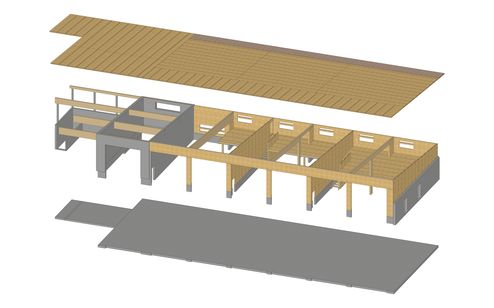

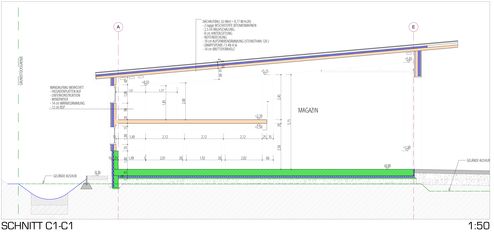

The office complex is a solid construction using mineral materials. All other buildings were constructed in wood. The structure was constructed using a combination of binderholz CLT BBS elements and glulam beams: 580 m³ of industrial quality BBS 125 and 45 m³ of BBS XL elements were used.

The system-based design of this concept using binderholz CLT BBS 125 elements requires a large degree of prefabrication, which improves and standardises the quality through work done in the workshop, significantly shortening the assembly time on site. The buildings are wind-proof and water-tight within the shortest time and there is virtually no damage caused by construction work on site, which, in turn, increases budgetary certainty. The projects can also be handed over to the end customer considerably earlier than when using conventional construction methods.

The execution in detail

The client relied on BBS elements in the storage area as well, on account of the high loads. The material’s high strength with a minimal thickness speaks in favour of its direct use and it enables heavier implements, such as snow shovels or metalworking equipment, to be compactly stored on several intermediate levels.

A large proportion of the power requirement is met by the buildings’ own photovoltaic system, with heat predominantly coming from an air heat pump.

Photos: © 2quadr.at, binderholz