Technical consulting

As a binderholz customer, you profit from our comprehensive consulting and solid service. The experienced experts in our strong technical department see to this. Our qualified engineers, construction technicians and draftspersons provide competent support for you in all matters relating to statics and design, building physics and fire protection. They are always a step ahead and not just at the level of the latest state of the art because of their many years of experience and intense research and development work.

Our offered services

• Advice on all constructive binderholz solid wood products and their application possibilities

• Static, building physics and fire engineering construction solutions and component evaluations based on our Solid Timber Manual 2.0

• Individual project consulting by highly qualified employees in the back-office and in the field with technical project consulting, who will also visit your site if required

• Advice on supplementary construction, sealing and connection materials

• Product-specific support for creating performance directories

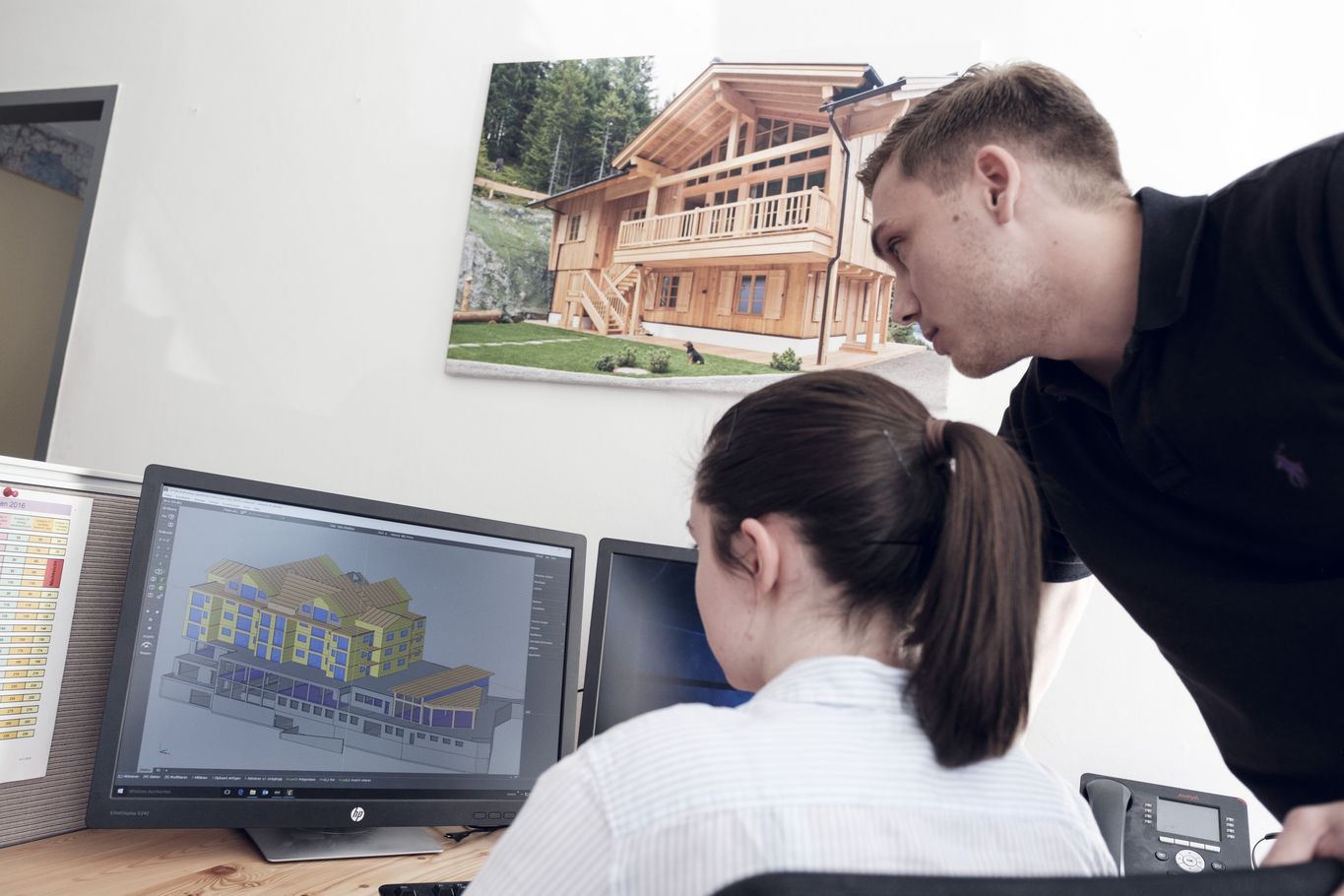

• We draw and work on state-of-the-art 3D CAD-CAM systems

• Optimised planning process through Building Information Modeling BIM

Our services subject to payment

• Work plans based on submission or polishing plans include the following services:

- Supportive coordination and communication with other trades or executing companies

- Incorporation of execution details according to building statics such as component dimensions, details of attachment and connection tools, etc.

- Incorporation of building physics details such as soundproof bearings, etc.

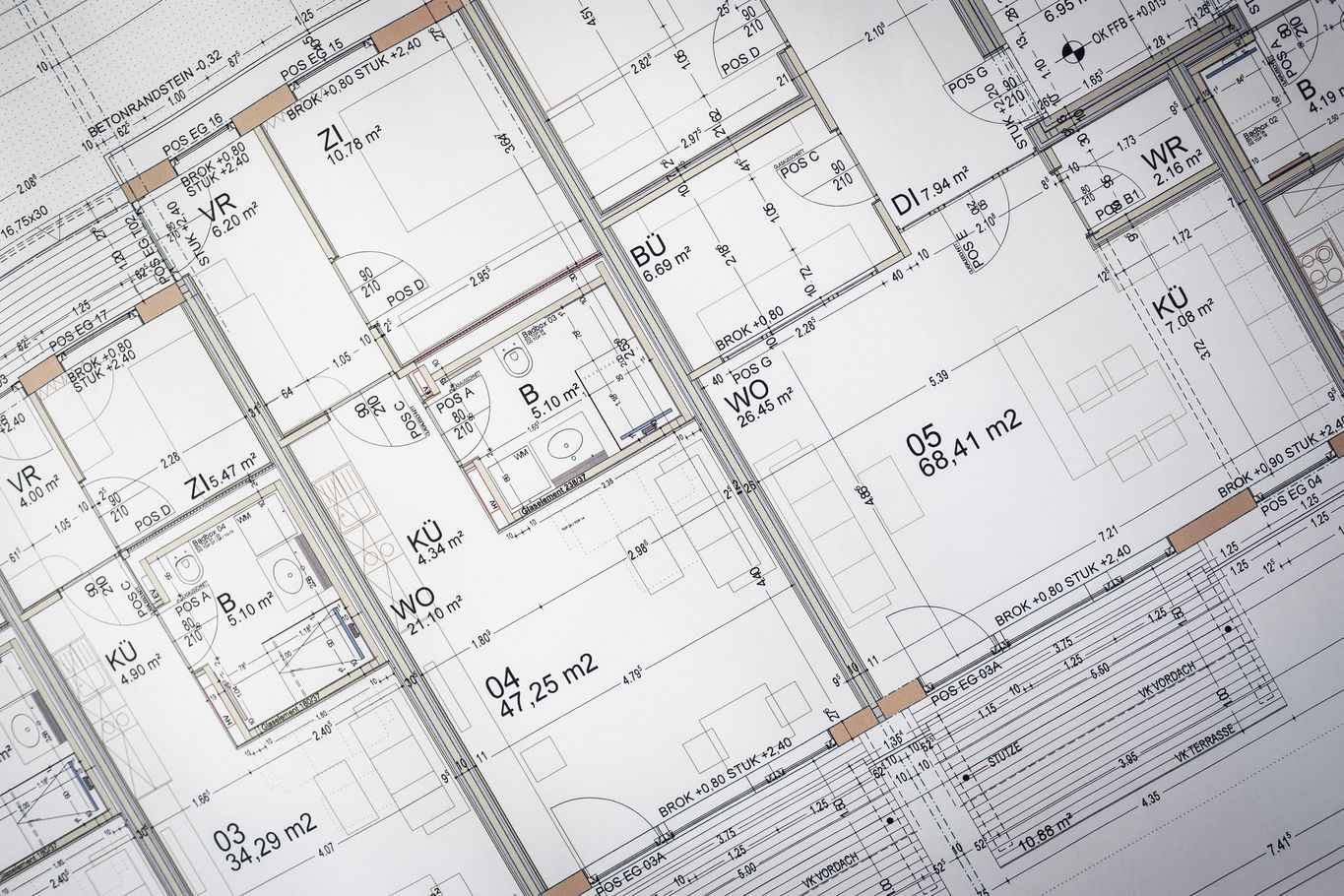

- Induction of electrical and building technology planning, etc. on 2D or 3D plan basis

- Output of floor plans and cross-sections

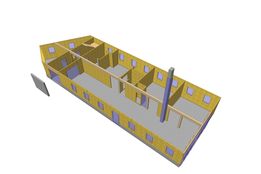

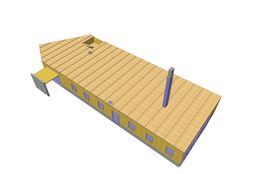

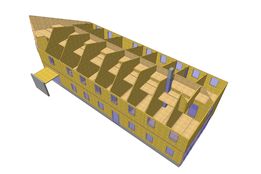

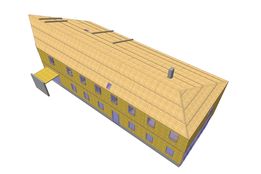

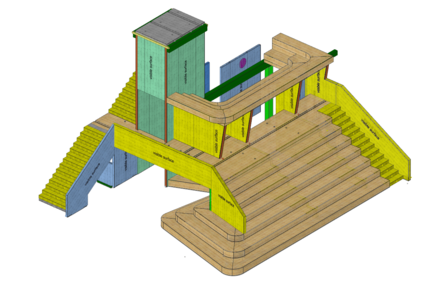

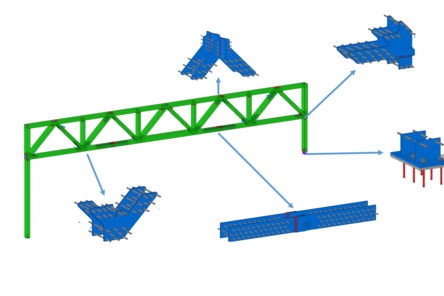

• Assembly plans for the construction of the solid wood shell (floor plans and cross-sections, 2D and 3D representations)

• 3D representations of the individual construction phases (axonometry)

• Loading plans for solid wood components

Building physics service

In the field of building physics, we are happy to advise you in the individual specialised fields of fire protection, sound insulation, heat and moisture protection.

Fire protection

Components must maintain their function in the event of a fire during the required period of time. The capacity of a component is dependent on the interaction of the individual layers such as the load-bearing structure, the insulating materials and the planking. To determine the fire resistance, comprehensive fire tests have been conducted on BBS elements at various independent and accredited testing institutions. In the fire tests, not only large-area BBS elements have been tested but also different connecting joints.

Wood has the capacity of building up a protective layer of carbon in the event of a fire. It has an insulating effect and thereby delays burn-off and fire propagation. The burn-off speed of binderholz BBS cross-laminated timber has been determined by comprehensive testing at accredited testing institutions. The carrying capacity of BBS components in the event of a fire can therefore be calculated with high accuracy.

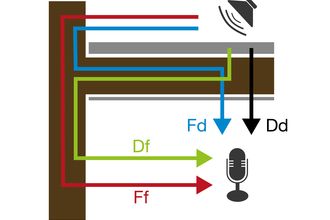

Sound insulation

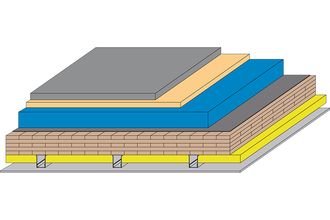

Sound insulation serves the purpose of protecting people adequately from noise in social rooms. In wood construction, components always comprise several layers. This way, the sound encounters multiple resistances on its path in between the individual components. In solid timber structures, foremost the total thickness of the binderholz BBS cross-laminated timber, its surface weight and flexural stiffness play an essential role for the sound insulation of the basic component (without further layers).

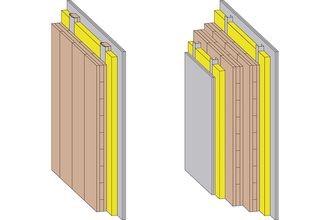

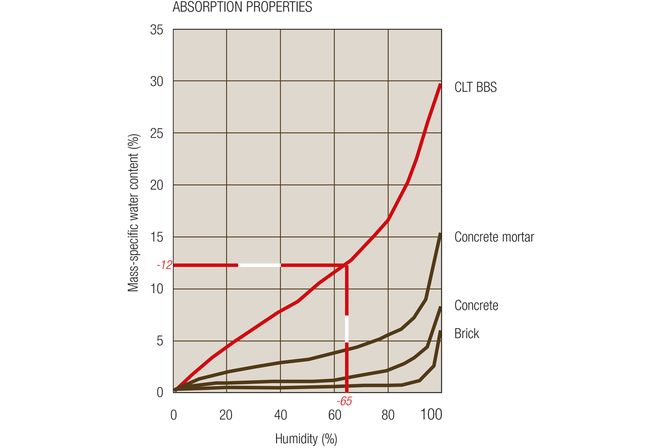

Heat insulation and moisture regulation

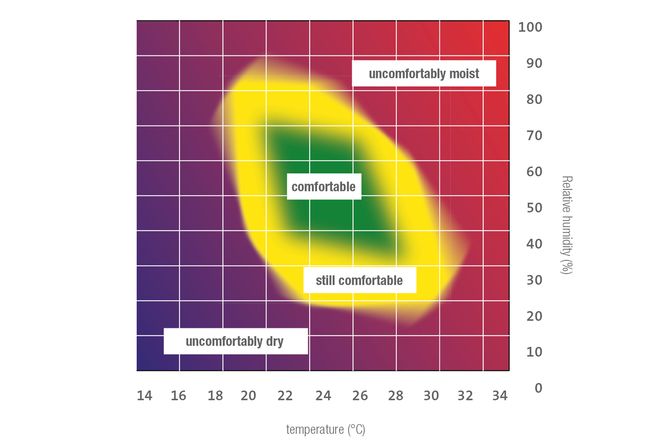

Heat insulation in construction above ground level covers all measures to avoid a need for heating during the winter and cooling during the summer. At the same time, more comfort because of a pleasant room climate and the related significant relief for the environment are key points.

With BBS, low energy, passive energy and plus energy buildings can be constructed. BBS structures fulfil all customary heat insulation values and create a comfortable and balanced room climate due to their permeable design and their capacity to lower the peak values of the humidity in the room.

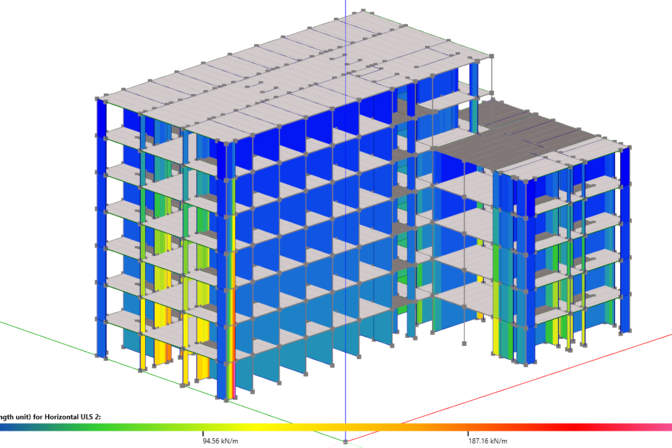

Preliminary static measurement

We are at your side for developing building concepts, draft plans for the load-bearing structure and detail solutions, with advice based on the many years of experience of binderholz in solid timber construction to support you professionally. Our engineering team accordingly develops adjusted concepts for carrying structures based on the plan and information documents provided by the customer, which will lead to optimally planned and economically feasible projects in solid timber construction, in part combined with components made of steel or other wood materials.

binderholz structural analysis software

binderholz provides designers and customers the following structural analysis software solutions free of charge.

binderholz DC Statik software

The software company Dietrich’s has developed in collaboration with binderholz this company-specific version of a design program for solid wood constructions. binderholz DC Statik is free of charge for our customers. In addition to project management, the program contains various input interfaces for measuring CLT BBS ceilings, roofs, walls and beams. The extensive material data supplied, the easily comprehensible tools and the automatic determination of the loads render any complex search for information in other sources unnecessary. The automatic generation of the evidentiary documents, with a clearly recognisable grading, ensures the verifiability of the evidence.

Wallner Mild wood construction software

With this Excel-based program, binderholz CLT BBS building components such as walls, ceilings, roofs and beams can be easily measured. The calculations are carried out in accordance with Eurocode 5 (EN 1995-1) taking into account the country-specific national annexes and are documented in a component-specific printout.

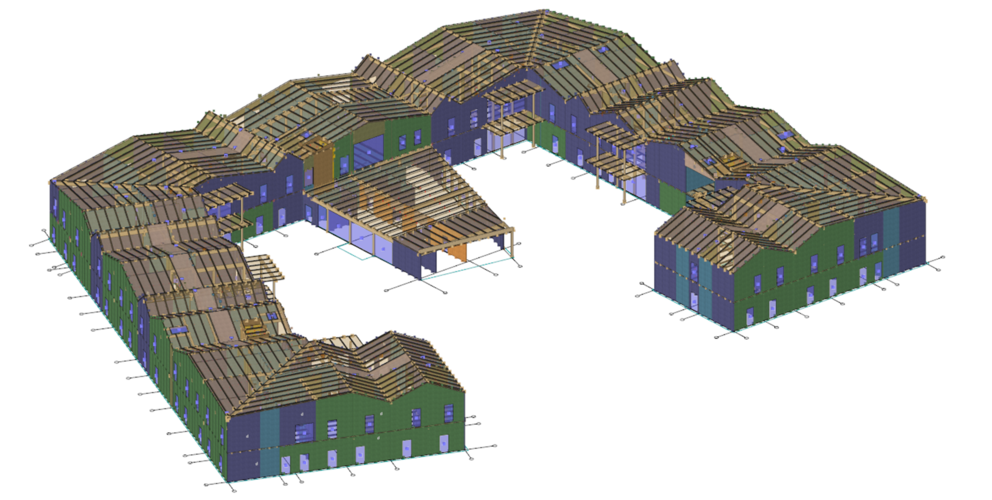

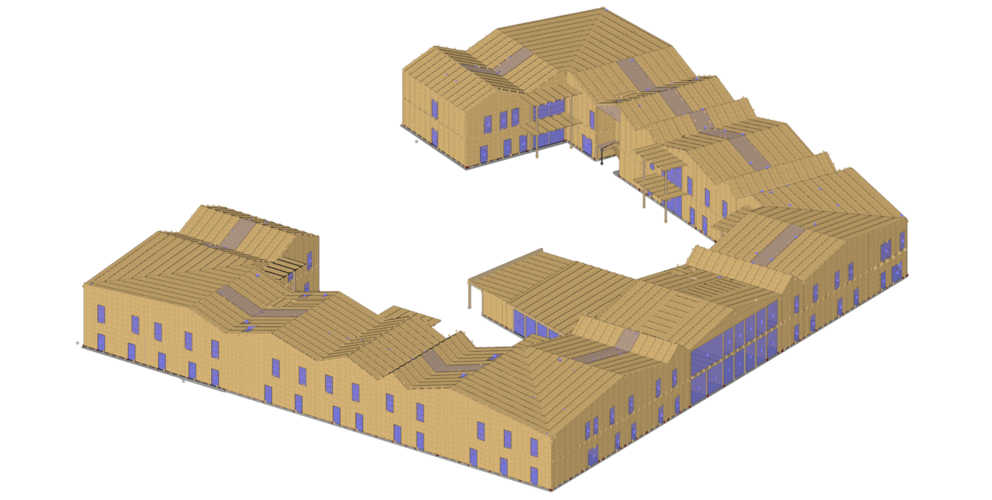

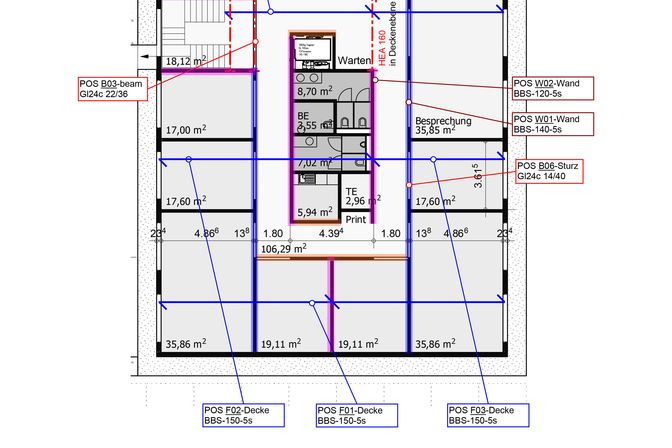

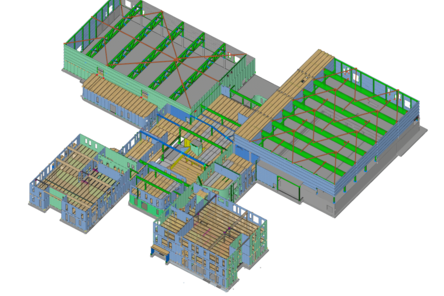

Technical planning and work preparation

Precision starts in work preparation. Therefore, our technicians prepare a 3D CAD model for each project that is executed using binderholz solid timber products to produce the individual solid timber components. The production data generated in this step will subsequently be transferred directly to the respective assembly plants. This guarantees processing of the solid timber components precise to the millimetre.

binderholz permanently works on integrating BIM (Building Information Modelling) even more closely in the planning process. This has a significant benefit foremost in large-scale projects, as the BIM considerably minimises the susceptibility for errors and enables a more precise interconnection of the interface between the different active planners, consultants, companies and trades.

Project planning

Depending on the project and only on request, the building statics and the entire works planning for the wood construction will be furnished in the binderholz project department. The solid timber components and the statically required elements made of other wood materials, all related details and the connection, for example, to the foundation or the elevator shaft, are therefore planned and delivered from one source by binderholz. This way, the number of the points of contact with external planners is reduced, minimising the susceptibility of errors in the planning process and improves the project processing time.

Workflow of project planning:

• On receipt of the required plans and informational documents, binderholz takes over the planning of the BBS elements. In this case, we will discuss details directly with the customer. Delivery of the verifiable overall statics concept for the structures delivered by binderholz is possible; all costs for this must be paid by the customer.

• The customer will receive a complete set of installation and assembly plans that include wall, ceiling and roof overview drawings, and floor plans for the wall positioning.

Specific planning details are, for example:

• Timber sill plans

• Panel splits (module planning for components in the panel dimensions offered by binderholz)

• Phase splits (division of the overall project into construction sections depending on customer requirements)

• Organisation of the complete transport logistics from the mill to the place of use

• Support through supervision at the construction site

• Delivery period: The exact delivery period can be assured only upon clarification and approval of all assembly plans. Delivery periods always apply as of the plan approval for our assembly plans.

• Costs will be indicated on request

Contact

Want to find out more? Please contact us directly on fon +43 6245 70500-0. For US sales please contact +1 706 773 7753.

On request, we will gladly send you more detailed information material. Please complete the form. All fields marked with * are mandatory.

The data from the contact form is sent to various departments within binderholz’s companies to process your enquiry. Find out more about our data protection here.