Wenlock Road, London | Great Britain

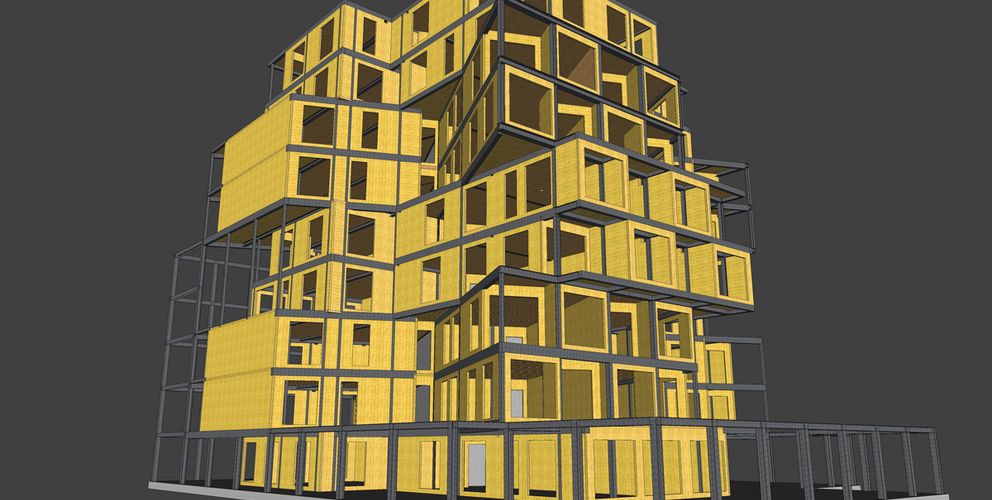

The architects Hawkins/Brown were commissioned by Regal Homes to build Europe's tallest hybrid cross-laminated timber high-rise building, and binderholz Bausysteme jointly with X-LAM Alliance delivered Austrian wood and know-how to Great Britain. Regal Homes was awarded planning permission for a 10-storey residential building in London using a hybrid construction of BBS and steel with a usable space of 6,750 m², thereby setting new standards in solid timber construction.

facts

Project GB's tallest hybrid timber building

Place London, Great Britain

Construction 2015

Client Regal Homes

Execution X-LAM Alliance

Architecture Hawkins/Brown, LLP London

Details

The property on Wenlock Road in Hackney, East London, provides a total of 4,650 m² of living space with 50 residential units and 1,190 m² of commercial space. Due to the unusual cruciform architecture, reminiscent of an Asian Banyan tree, the building offers an unrivalled light and terrace concept providing a unique quality of living in the middle of the city, blending perfectly into the Regent's Canal district. The twist of the cruciform floor plan has a quite unique effect on the views of the city, with the majority of the apartments experiencing two and many even three different impressions of London from the same apartment.

Building Information Modelling (BIM)

Building Information Modelling is (still) relatively unimportant in timber construction in the German-speaking world, whereas in Northern countries and in Great Britain BIM is also called for in timber construction on many larger projects. It was thus a fundamental prerequisite with this major project in London that all trades involved with the construction could provide relevant BIM experience. The material complexity, specifically with hybrid construction solutions involving solid wood, steel, concrete and glass, can be best portrayed using BIM processes and implemented in a quality-assured manner in the design process. BIM is becoming increasingly important for binderholz when it comes to cooperating and installing large international projects.

All parts had to be delivered just in time owing to the very tight conditions on site. The parts for the next floor could not be stored on the street, as is usually the case, rather always had to be stored directly on the ceiling below just finished.

binderholz delivered 1,400 m³ of CLT BBS and made its mark with its experience of solid timber construction. The building is clad in slatted cedar, while the street elevation along the Wenlock Road is finished with brick tiles.

The benefits of CLT BBS are manifold - from reducing the overall weight of the building, resulting in massive savings with the foundation, to its impressive physical construction advantages, such as air-tightness, the thermal insulation of the material and its acoustic properties. The CLT BBS elements prefabricated in the factory had precise dimensional stability and could be unloaded from the lorry without major work.

Awards | Prizes

The complexity and outstanding architecture of this magnificent project also succeeded in winning over international judging panels. Here are just a few of the awards presented to Wenlock Road:

2015 Off Site Awards 'Winner of Winners'

2015 Structural Timber Awards 'Engineer of the Year'

2015 Celebrating Construction Award for Innovation

2015 Evening Standard New Homes Award

2013 International Property Award in the Mixed Use Architecture category

Photos: © Hawkins\Brown Forbes Massie, binderholz