Love for wood

resource efficiency

This is where it comes full circle - resource efficiency at binderholz

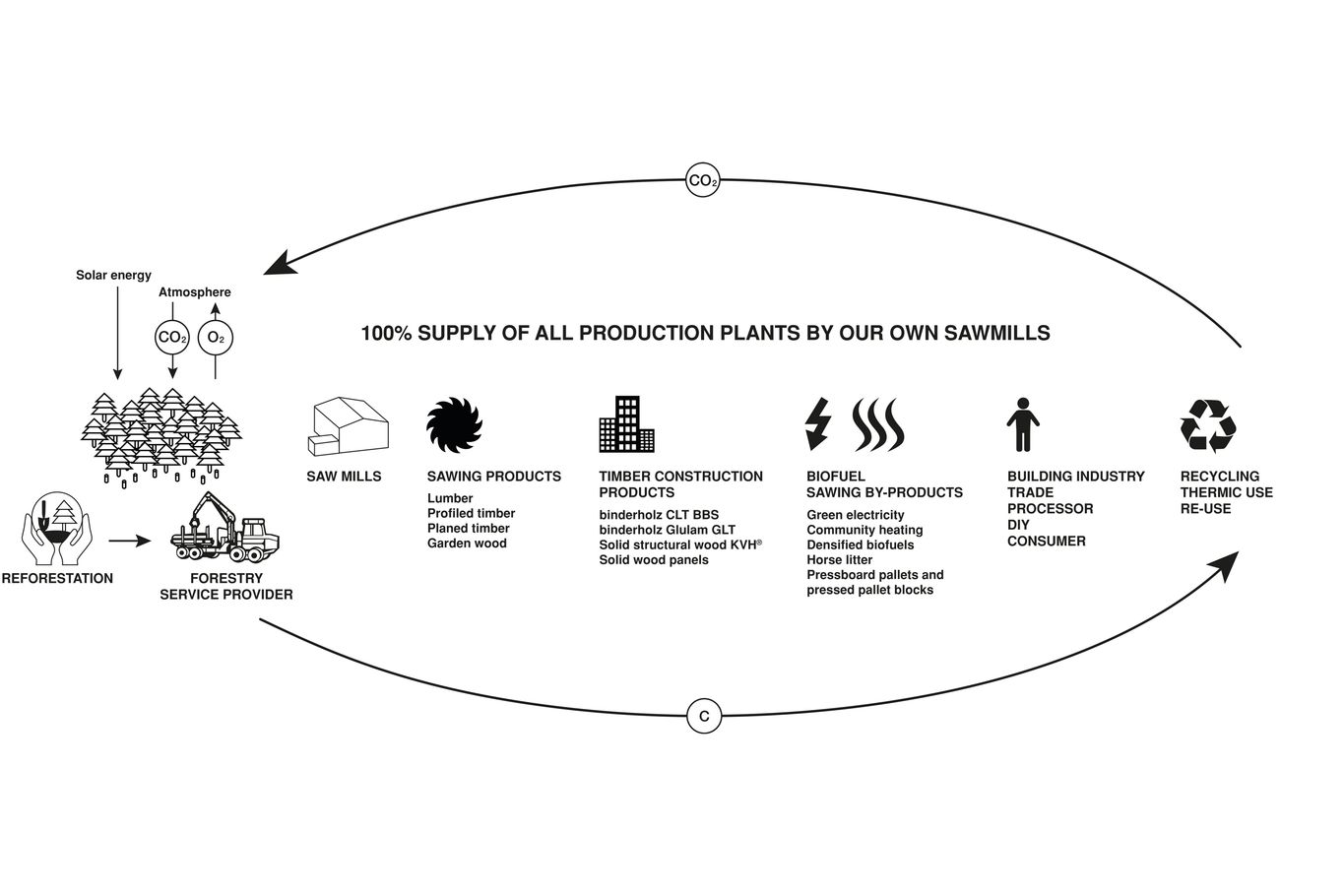

binderholz stands for a responsible use of wood as a natural raw material. We process the entire trunk - from the core to the bark - thus ensuring 100 percent value creation. Solid timber products come into being that have been produced efficiently and sustainably and conform to the highest requirements. Let's take a look at the main sustainability factors to demonstrate how we achieve such a high degree of resource efficiency.

Raw material

100% use of wood as a raw material based on a 'zero waste' principle

The binderholz value creation chain is based on the principle of 'zero waste' .This means that 100% of the timber raw material is processed.

After their delivery, binderholz processes the trunks nearly completely into sawn timber, solid timber panels, glulam and CLT BBS. Waste timber as production by-products such as bark, cut-off pieces, wood chips, sawdust and shavings are processed into biofuels in the form of pellets and briquettes or converted into climate-neutral thermal energy or green electricity in our proprietary biomass combined heat and power station. Thus valuable resources are preserved and climate-neutral production without waste according to the zero-waste principle is made possible.

Energy

binderholz constantly monitors and optimizes the energy efficiency and resource consumption of all its production processes and facilities, applying state-of-the-art energy management systems.

These systems meet all internationally valid standards (ISO 50001) and comply with the increasingly stringent statutory requirements for energy efficiency. In some areas, they are also regularly monitored by independent third parties.

Active climate protection

binderholz products and construction solutions afford a dual protection of the climate. For one, CO2 taken from the atmosphere is stored in solid timber products for many decades to come. Concurrently, solid timber products replace conventional building materials that require fossil fuels for their production.

Sustainably grown wood as a raw material is one of the most important natural CO2 reservoirs. Trees need the climate-damaging gas to grow. They extract it from the atmosphere through photosynthesis, and it remains stored in solid timber products from binderholz for decades. In addition, products and construction solutions by binderholz take the place of many conventional building materials for whose production a huge amount of CO2 from fossil fuels is released. This way, the use of wood as a raw material slows down the rise of CO2 in the atmosphere and verifiably reduces the greenhouse effect.

Recycling

Building activities account for a large proportion of today's waste volume. And yet, up to 90 percent of construction site waste could be avoided by recycling. The key to it is wooden building and system solutions made from solid timber, because they have an especially high utilization and recycling potential.

One of the most outstanding features of binderholz construction solutions is their easy handling. Ideally, once they've reached the end of their building life, they can be removed as a complete building component and reused, or they can be used as energy source. In the latter case, they replace fossil fuels and thus contribute to climate protection.

binderholz develops construction solutions that are particularly suitable for reuse so as to boost utilization efficiency even more. This means building materials are combined with one another in the planning process and later integrated in the building such that they can be easily separated from one another again at the end of their useful life. This “design for recycling” guarantees an ideal material recovery. If, on the other hand, the focus is on energy use, a “design for energy” is realized.

Thanks to their ecological soundness, all binderholz products can be ecologically recycled, recovered or used as CO2-neutral fuel for the generation of electrical and thermal energy.

The use of wood as a raw and building material also helps with the life cycle assessment (LCA) of a building, conducted according to applicable certification systems such as LEED, BREEAM or DGNB. Because the use of construction solutions made from solid timber reduces the waste volume at the end of a building's life cycle and increases resource efficiency as a whole. That is why the following is true: Selecting the right material today helps avoid the waste of tomorrow.

Products and construction solutions from binderholz combine all the aforementioned benefits of wood as a sustainable raw and building material.

innovation

Innovation with tradition

binderholz stands for innovation. Because progress and advancement have been the driving forces of the company ever since its founding in 1950. The company chronicles reflect it, and the constant development of the product and service portfolio prove it. A small sawmill operation at the onset of our history, the company has grown into one of the leading European manufacturers of products for timber construction and a supplier of one-stop solutions for solid wood construction. With the development of timber construction products and construction solutions, binderholz constantly focuses on the most efficient manufacturing and production processes, based on cutting-edge production technologies. The sustainable use of resources as well as the development of innovative product properties and their integration in construction solutions customized to the client are also vital goals.

Future Developments

t is imperative to make even better use of the outstanding material qualities of the raw material of timber. That's exactly what binderholz strives to do, carrying development forward. This way, constructions are created that are particularly compact and lightweight in comparison to conventional solutions. In addition, they feature a high degree of prefabrication and top-flight workmanship. So-called hybrid solutions, i.e. combinations of solid timber and other materials, broaden the range of possibilities even more.

All binderholz developments are designed so they do not only conform to the requirements of building laws specific to different countries but, instead, go beyond them: what you get today will already comply with the standards of tomorrow. In the process, all aspects of statics and construction (dimensioning), structural physics (fire, noise, heat), ecology (life cycle assessment, carbon footprint, ecobalance, embodied energy), environmental and room hygiene (healthy housing), recycling (NO WASTE) and recovery (REUSE) are taken into account.

To this end, binderholz collaborates with independent test institutes and renowned specialists. The result pays off in all-around carefree packages for customers - made up of innovative building products and construction solutions for which all technical, commercial and ecological key figures, including those relevant to health, as well as all required certificates and documents are on hand.

Innovative Applications

The key indicator for every innovation is its suitability for everyday use. That is why binderholz collaborates with users and key partners from industry, commerce and science. For instance, we closely collaborate with Saint Gobain Rigips, Austria, and the WoodKplus excellence center for timber in Tulln. The clustered know-how and experience of our partners are systematically integrated in our new developments and enhancements.

This way, construction solutions ready for assembly are created for our customers. For example, structures for walls, ceilings and roofs, finalized in every detail regarding statics, structural physics and fire protection, as well as innovative connections. Practice-oriented application guidelines, e.g. for fire walls, noise and heat insulation, as well as those addressing topics of healthy living are also in place.

The construction solutions and application guidelines of binderholz are comprehensively checked and evaluated prior to publication. The benefit for the customer: Since all certificates required under the building law are already in place, the planning costs can be reduced considerably and a sustainable, resource-efficient and economical timber construction be guaranteed.

In order to ensure maximum future viability and anticipatory planning, binderholz is also active in numerous industry initiatives and plays a part in the formulation of future construction standards.

Service for users

Products and construction solutions by binderholz make the planning, designing and building process easy. This is ensured by a broad range of services, from the Manual for Solid Timber Construction, with its detailed descriptions of structures for walls, ceilings and roofs, to the company's comprehensive testing, approval and certification work. All products and construction solutions conform to all applicable standards. They are also certified according to standards specific to different countries.

So planners and architects can easily access the core parameters, all binderholz construction products are listed in the most renowned databases for building materials - among them the Rigips database, the Austrian "baubook" database for building ecology and the Swiss Timber Association Lignum.

Quality

Top quality is a must. We owe this to ourselves and, above all, to you.