binderholz office building, Lieksa | Finland

Only a 5-month long total construction period

The sawing mill sites in Lieksa and Nurmes in Finland have been part of the binderholz group since January 2016. A new administration and office building, with a total of 37 workplaces, was constructed on the site of the sawmill in Lieksa to provide for the central management of both sites. The planning phase started in April 2016, the foundation work began in July and the offices were ready to move into in November 2016.

facts

Project Office building with BBS Thermo wall

Location Lieksa, Finland

Year of construction 2016

Client Binderholz Nordic Oy

Execution of timber construction Holzbau Rast & Ruh GmbH, Holzplus e.U.

Architecture Arkkitehtitoimisto Arcadia Oy, Binderholz Bausysteme GmbH

Statics HM-Suunnittelu Oy, Binderholz Bausysteme GmbH

Wall construction

Pleasingly simple!

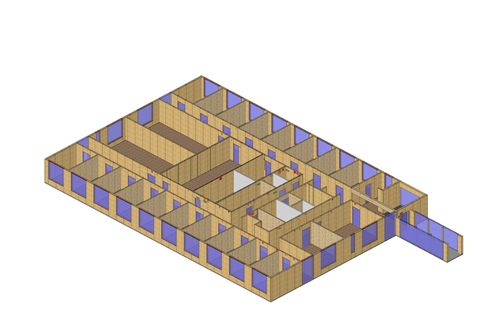

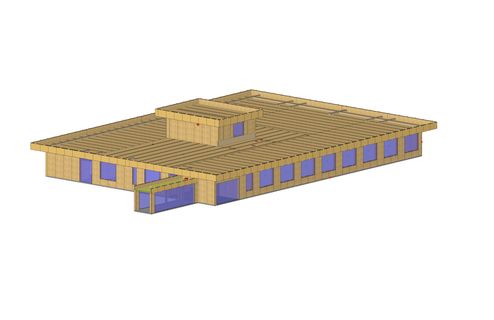

The single-floor office building has a clear room structure with efficient partitioning. The load-bearing outer walls were constructed with what are known as BBS Thermo elements: 24 cm-thick binderholz CLT BBS walls without any additional thermal insulation. All the load-bearing structural components have visible quality timber finishes on both sides. The visible surfaces in the interior of the building are supplied in white glazed spruce wood from the Lieksa sawmill, with larch on the outside. Initial measurements show that the single material structure of this wall have a positive impact on the energy footprint. This special construction represents a transfer of knowledge to Finland, as this method of construction has not yet been employed here to date.

Concentrated power

Five Binderholz Nordic Oy sales employees have relocated to Lieksa from the office in Nurmes. The entire administration of both sawmills is thus concentrated at a single site, creating considerable benefits in terms of cooperation within the sales team, with other departments and providing the best possible customer care.

This schedule could only be achieved with a perfectly oiled team. The design, as well as the timber construction statics, were handled by binderholz’ Construction Systems team in Hallein. binderholz employees from various sites were involved in the installation phase. The entire design concept is based on the binderholz CLT BBS 125 grid, the precision of which enabled the construction to proceed with minimal wastage and thus more cost-effectively. A total of 350 m³ BBS 125 elements were fitted. The solid wood products were delivered to Lieksa from production sites in Austria and Germany.

Implementation

All solid wood products were delivered to Lieksa from the production sites, including:

- 3 layer solid wood panels in visible quality Finnish spruce for the non-load-bearing intermediate walls and in larch for the parapet wall cladding outside

- Glulam beams for static load deflection

- binderholz CLT BBS throughout for the entire wall and ceiling construction

binderholz’s electricians from the plant in Fügen supervised all electrical installations and worked closely with the contractors on site. The team from Fügen thus did all the KNX programming for lighting control, installed all locking systems for the office doors and programmed access permissions.

Coating

binderholz relied on proven Tyrolean quality for coating the timber components. ADLER’s Pullex Wood Oil (Natural) protects the larch parapet wall outside from the adverse weathering impact of the far North. ADLER Lignovit Interior UV100 in shade Grossglockner was used for all the interior wall and ceilings. The elegant whitish glaze produces a friendly and bright working environment and protects the wood from unattractive yellowing. The sophisticated parquet flooring, which harmoniously completes the stylish impression, comes from the binderholz parkett+mehr shop in Fügen. The parkett+mehr team laid some 800 m² of knotty oak planks, brushed and matt lacquered, in under 2 weeks.

Photos: © Holzbau Rast & Ruh GmbH, binderholz

Plans: © binderholz